Industrial Copper Wire Granulator

Brand: Shuliy

Model: SL600, SL800

Function: Its main function is to crush and screen waste cables to separate them into copper and plastic.

Capacity: 100Kg/h – 1T/h.

Particle size: about3mm,can be customized.

Standard processable wire diameters: <20mm,

Processing larger diameters requires additional shredders, and we provide customized solutions.

Warranty: 1 year.

Advantage:Chinese factory, 15year R&D experience, high cost performance, fast delivery.

Service: Free customized slution. Installation and debugging. Free training operation. Welcome to visit our factory.

The Raw Materials And End Products Of A Copper Wire Granulator

Types of Wires That Can Be Processed:

Communication wires: (e.g., telephone lines, data cables) – thin wires, easy to process.

Household appliance wires.

Automotive wires: (May be more difficult to process due to thinner cores and mixed materials).

Industrial power cables: (Usually require pre-shredding due to their larger diameter).

How Does A Copper Wire Granulator Work?

A copper wire granulator is a sophisticated recycling machine designed to efficiently separate copper from its plastic or rubber insulation (and sometimes other metals), producing high-purity copper granules.

Here’s a detailed breakdown of the copper wire granulator’s working principle:

Core Principle:

The machine utilizes the differences in density and physical properties between copper and plastic, combining crushing, vibration, and airflow separation techniques for separation.

Step-by-Step Process:

- Feeding:

Scrap insulated copper wires of various sizes and types are fed into the machine’s hopper via conveyor belts or manually.

For thicker cables, a separate pre-crusher is often used to pre-crush the material for smoother processing. - Primary Crushing (Granulation):

The wires are fed into a rotating granulator or crushing chamber equipped with hardened steel blades or rotors.

Here, the material is shredded and crushed into uniform small pieces (typically 3-10 mm). This process breaks the bond between the copper core and the insulation without melting or altering the chemical properties of either material. - Separation Stage:

Airflow Separation/Vibrating Screen:

The mixture of copper granules and plastic/rubber fragments (now called “granules”) falls onto a vibrating screen or airflow separation system.

Vibrating Screen: The granules are sorted by size. Appropriately sized mixtures continue forward; oversized granules are typically returned to the crusher for secondary crushing.

Airflow Separation (Aspirator): This is the crucial separation step. A controlled stream of air is blown across the falling granules. Due to their lower density, the lighter plastic/rubber fragments are blown away by the airflow into a separate collection bag or bin. The denser copper granules, unaffected by the airflow, fall straight down. - Collection:

Copper Output: The separated, pure copper granules are collected in bags or bins. They can now be sold to copper smelters or foundries for smelting and reuse.

Plastic Output: The separated plastic/rubber fragments (often called “fluff”) are collected separately. While of lower value, this material can often be sold for use in the manufacture of plastic lumber, building fillers, or other recycled plastic products.

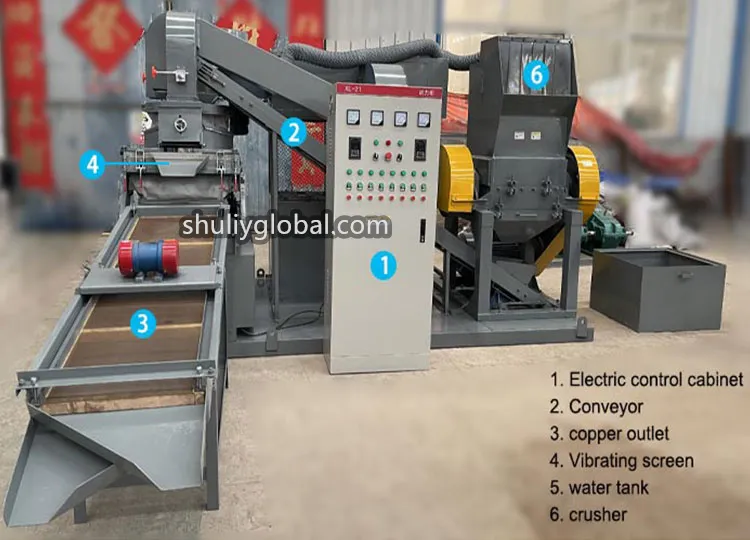

Structure Of A Copper Wire Granulator

Standard copper wire granulator specifications

| Model | External dimension (mm) | Crusher (KW) | Air conveying (KW) | Wind sorting (KW) | Dust collection (KW) | Output (KGH) | Weight |

| SL-400 | 2000*1850*2600 | 15 | N/A | 0.75+22 | 0.75 | 100-150 | 1800 |

| SL-600 | 4200*1900*3800 | 37 | 3 | 3.75 | 2.2 | 300-400 | 3500 |

| SL-1000 | 5180*2100*4200 | 45 | 4 | 3.75 | 3 | 800-1000 | 4600 |

Advantages of Copper Wire Granulation Machines

High Purity, High Yield: Achieves over 99% pure copper separation, maximizing profits.

Environmentally Friendly and Safe: No incineration required, eliminating toxic fumes (e.g., dioxins produced from burning PVC).

High Efficiency: Can automatically and quickly process large quantities of wires.

Dual Revenue Stream: Allows for the simultaneous sale of pure copper and plastic, creating a dual income source.

Ensures Worker Safety: Eliminates the dangers of manual wire stripping (cuts, ergonomic injuries) and the risks associated with incineration.

Shuliy Copper Wire Recycling Machine Factory Manufactures And Delivers.

During the process of shipping the copper wire granulator to the customer’s country, factory employees cooperate with transportation personnel to handle the packaging and loading of the machines before shipment.

Shuliy Copper Wire Recycling Machine Processing Workshop

Shuliy copper wire recycling machine shipment

Related Best-Selling Machines

wire stripping machine