Línea de producción de gránulos de espuma

Línea de reciclaje de espuma de plástico / Línea de pelletizado de espuma de plástico

Capacidad: 100kg-500kg/h, 1t-5t/h.

Longitud de las partículas: 4 mm (convencional), se puede personalizar.

Diámetro de partícula: 3 mm (convencional), se puede personalizar.

Garantía: 1 año.

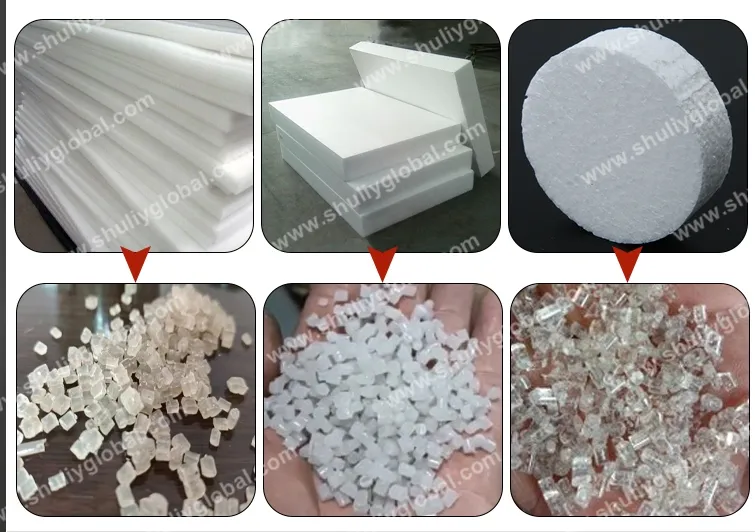

Ingredientes comunes de espuma de botellas de plástico: PS, EPS, XPS, PVC, PE, PP, EPP, EPE, XLPE, PEX, PU, FPU, RPU, etc.

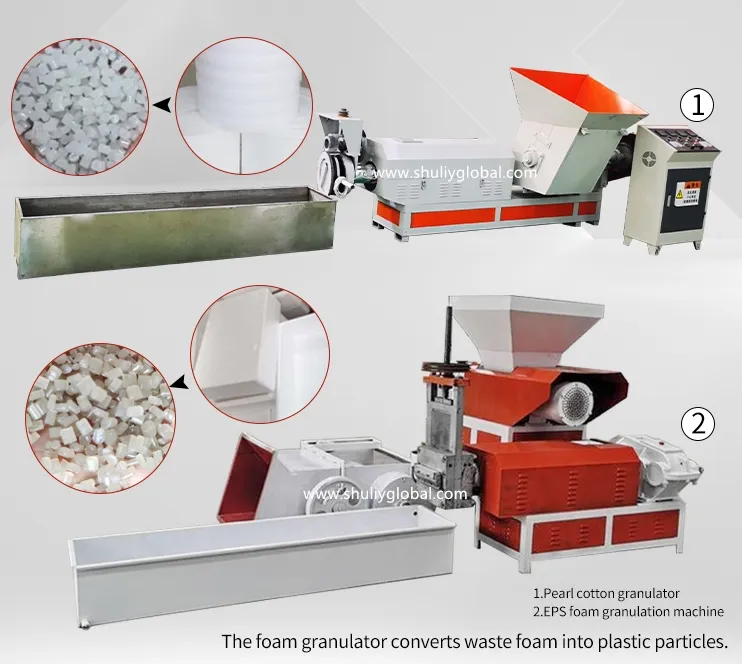

¿Qué máquinas incluye la línea de producción de gránulos de espuma?

1. Ventilador de succión: Soplado de espuma para que la espuma entre en la entrada.

2.Máquina de trituración: La máquina puede triturar la espuma en piezas pequeñas.

3.Máquina de fabricación de pellets: La materia prima se calienta y se funde en esta máquina, y la espuma fundida se extrae a través del dado en la máquina.

4.Tanque de agua: Se utiliza para enfriar el pellet de espuma y enviar el pellet al siguiente paso: máquina de corte de espuma.

5.Máquina de corte de espuma: Esta máquina se utiliza para cortar la tira de espuma en piezas pequeñas y el tamaño del pellet se puede ajustar según sus requisitos.

6.Máquina de empaquetado de pellets de espuma: empaquetando el producto final (pellet de espuma).

7.Armario de control: El armario de control de temperatura controla la temperatura de la máquina de pellets de espuma y también facilita a las personas operar la máquina.

¿Qué plásticos puede utilizar el granulador de reciclaje de espuma de plástico?

Ingredientes comunes de espuma de botellas de plástico: PS, EPS, XPS, PVC, PE, PP, EPP, EPE, XLPE, PEX, PU, FPU, RPU, etc.

Máquina de pelletizado de espuma de plástico EPS EPE en fábrica

Contáctenos para obtener más información sobre la línea de reciclaje de espuma de plástico